JACOBSIMEONE.NET

The Core One - Prusa's CoreXY Entry

Published: 2025-09-12

Image Credit: https://blog.prusa3d.com/introducing-prusa-core-one-fully- nclosed-corexy-3d-printer-with-active-temperature-control_105477/

It’s no secret Prusa is an industry leader in open, repairable, and sustainable consumer 3D printers. However, up until recently: there was a noticeable hole in their FDM printer line-up. Not one to disappoint, Prusa Research dropped a bombshell of an announcement in a blog post in November, 2024. They were releasing a fully-enclosed FDM 3D-printer with a corexy extruder and active temperature control.

First - How I Use 3D Printers and My Review Bias

It’s important to talk about the perspective I take when critiquing 3D printers, and my bias that I have developed over the years. I would not classify myself as a 3D printer enthusiast, a 3D printer to me is a tool to assist me in my other hobbies, and to develop tools for work. It is not a device that requires the majority of my time to maintain just so it can lay a first layer.

Typically, I use 3D printers to make parts, enclosures, and organizers for electronics. Like everyone, I also enjoy printing trinkets and other fun toys from time to time. When I start a print, I want to walk away and not have to worry about my print failing 50% of the time.

Throughout my journey, I have owned an Ender 3V2, and a Prusa Mk3 prior to the Core One. I manage a couple Prusa Mk4s printers and am very familiar with them, and have briefly interacted with a BambuLab printer once. I have dealt with the extreme ends of the scale of: “needing 20 minutes to get the first layer to stick”, and “hit print and walk away”.

In short: I have a bias. I want my 3D printers to just work, and I have not tried a BambuLab printer. As with any review on the internet, take everything I write a small part of a grain of salt. I am a fallible human being like any other.

First Impressions

My first impressions out of the box, build, and first print.

Holy this Box is Big

As always with Prusa, purchasing and shipping was no issue, the box arrived in good condition and was… noticeably larger than any other printer I have assembled in the past. The box has plastic handles on the sides to assist with lifting, but one of mine unfortunately broke off during shipping.

It is truly inspiring how well compacted Prusa engineers manage to make the packaging for their printers. This box was filled to the absolute brim with little russian nesting doll boxes inside of it, with no spacers.

The Build

This was the longest build I have ever done for a Prusa 3D printer. The whole build took me about ten hours, over two days. I could have done 9 hours if I wasn’t yapping to friends the whole time. Based off of some forums post, I was seeing reports of some taking 12-14 hours to complete the build.

The instructions were clear, but it was apparent that this was Prusa’s first fully enclosed printer, some of the final steps regarding putting together the enclosure felt a little hard compared to the rest of the build.

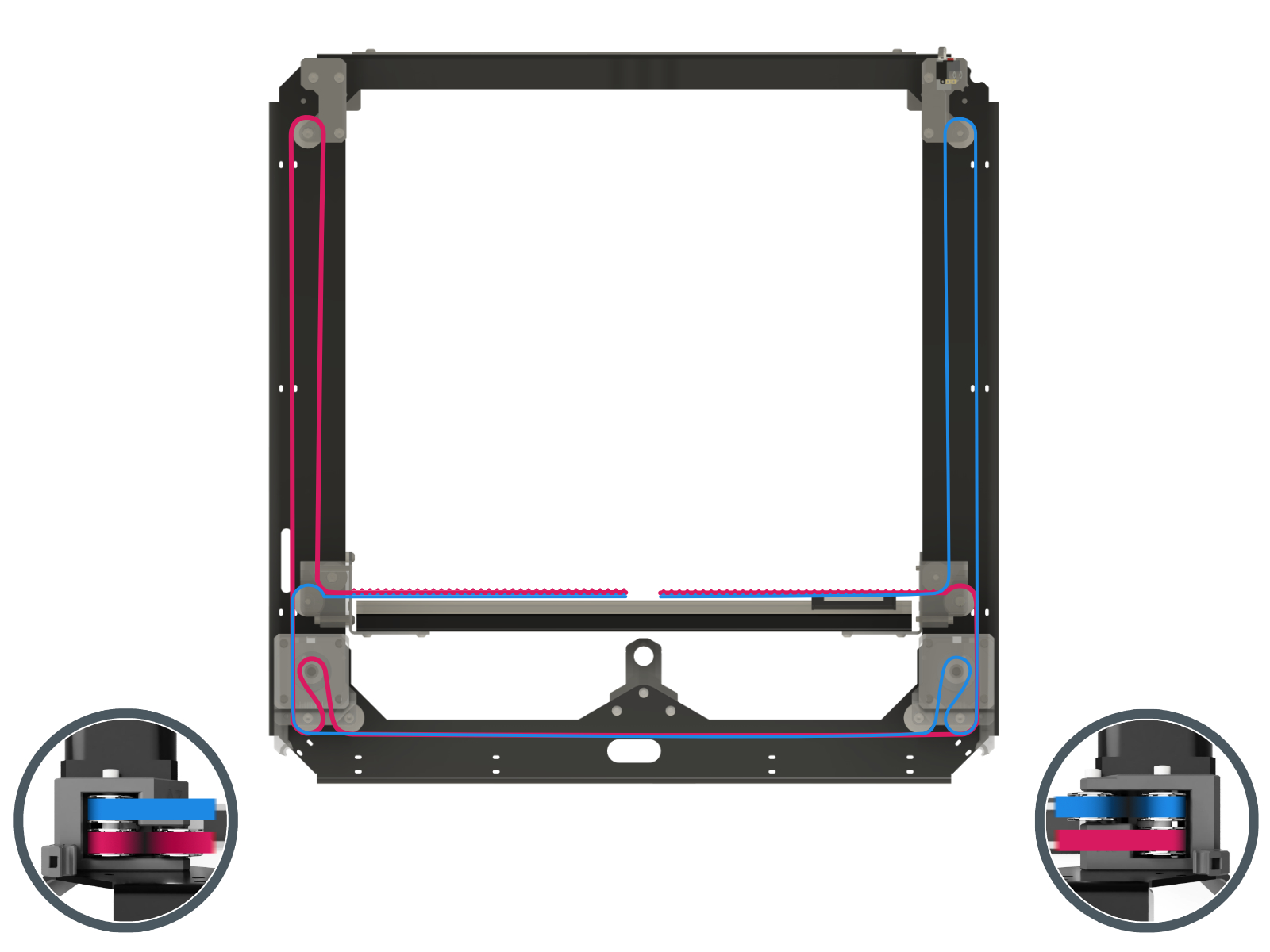

One part of the assembly I have great respect to Prusa for well documenting is the CoreXY belt assembly guide, it was well thought out with superb diagrams that made it super easy to follow. I was initially worried about this step, as CoreXY belt assemblies can be confusing to put together.

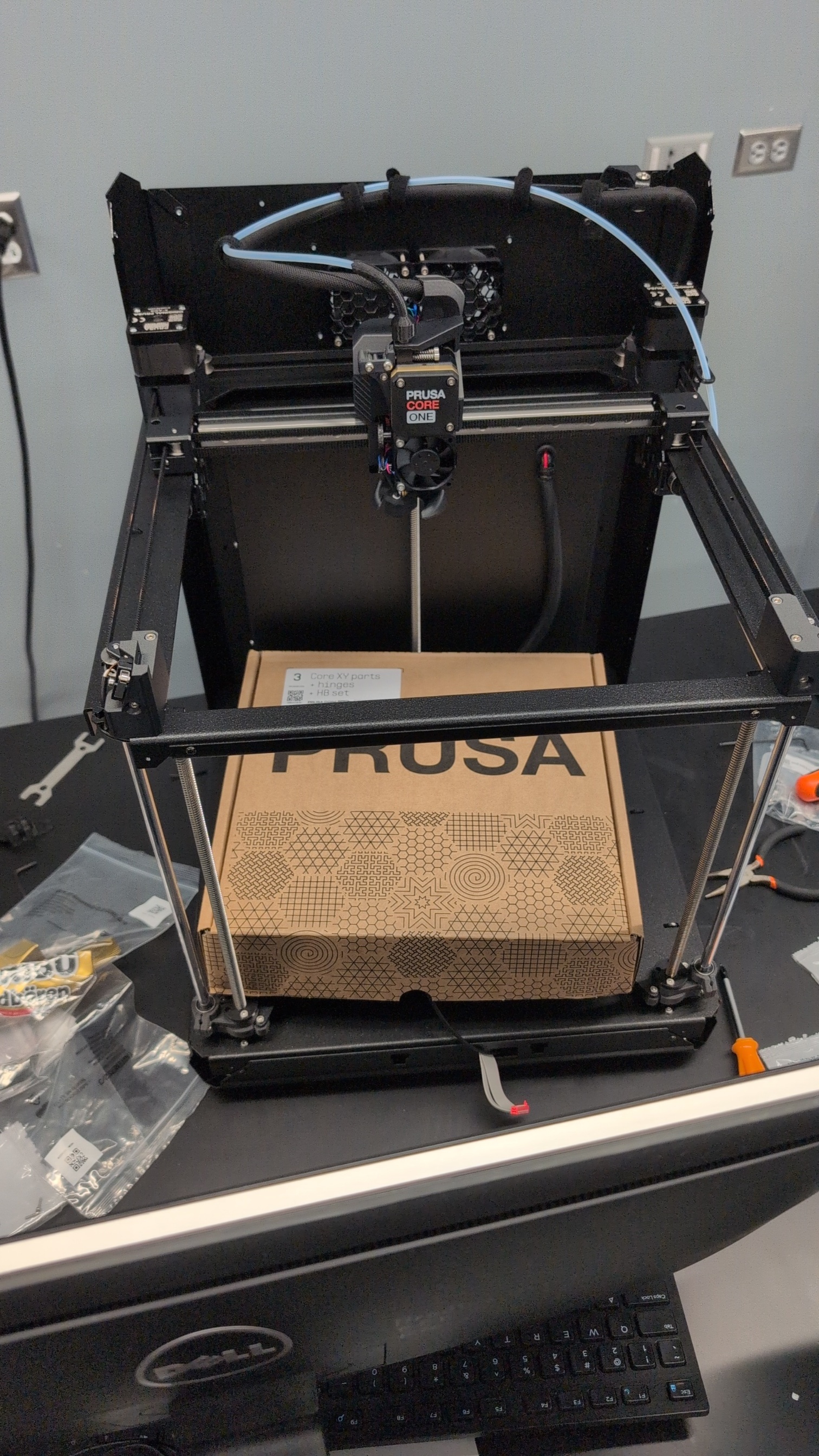

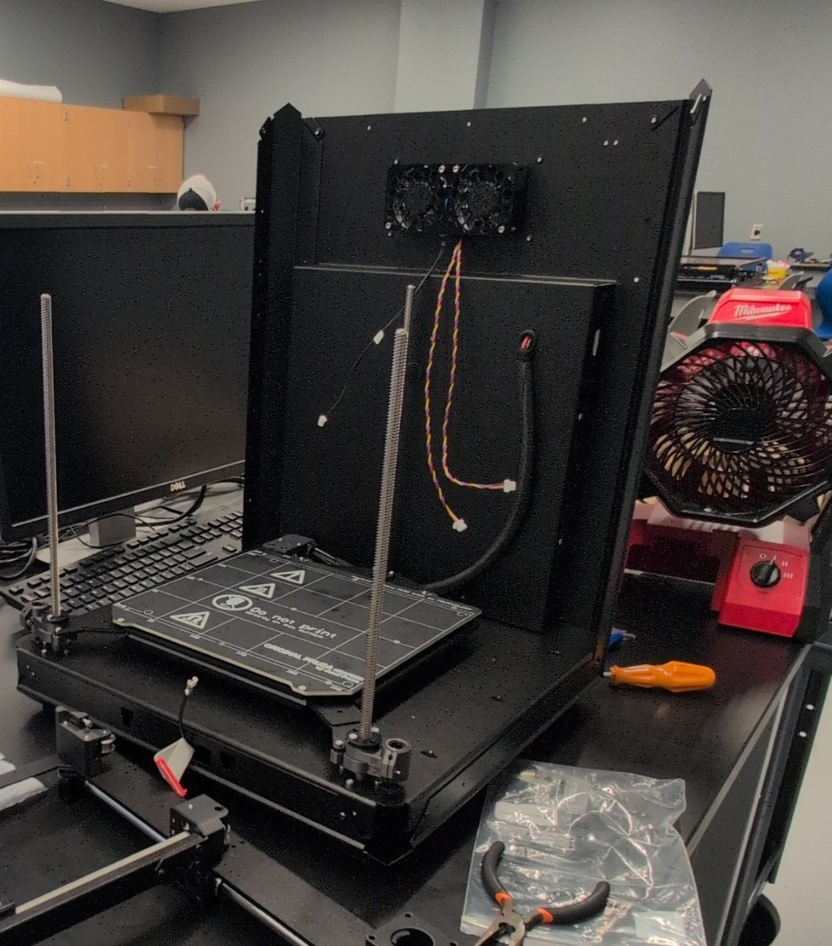

During the build, I noticed a couple of cool features that I did not see advertised as much in the flyers. For one, the printer now has 3 motor driven z axis screws for leveling, instead of the normal 2. You can see this in the image below:

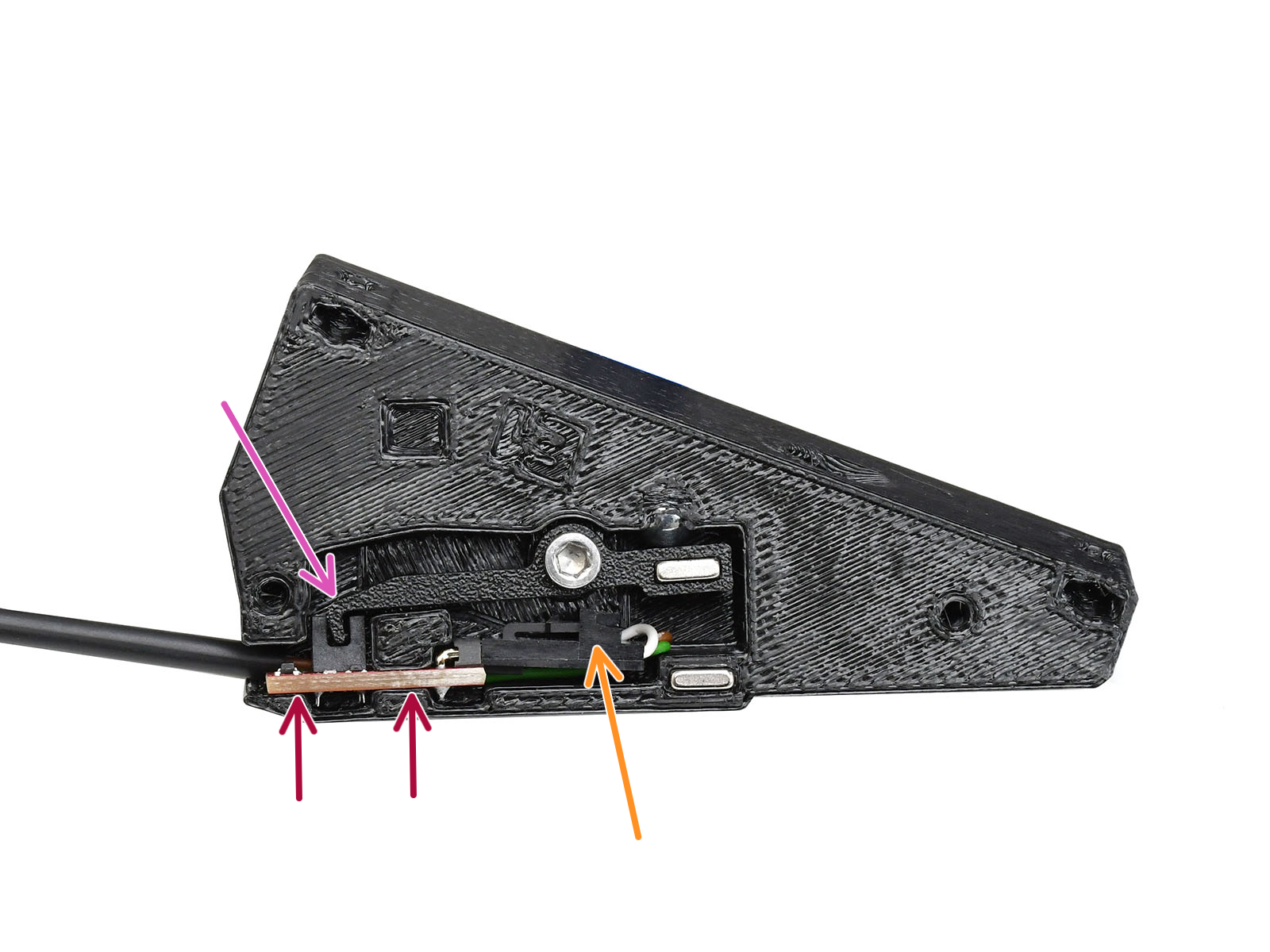

I also thought the filament sensor mounted near the spool was really cool. It uses a lever, magnet, and IR sensor system to detect if filament is present. You can see how this works in the image below:

If filament is present, the lever is pushed down against the magnet which acts as a spring, removing the tab from the IR sensor. If the filament runs out, the lever springs back up, and the tab blocks the IR sensor, noting there is no filament.

I have ran out of filament mid-print with this printer once already but curiously this sensor didn’t detect it. Turns out, I’m not the only one with this issue.

This forum seems to indicate that others have had issues with the sensor not working right first try for those that assembled their own kits. I was facing a similar issue where the magnet inside of the assembly was not inserted all of the way, causing the lever to not work properly. After quickly popping off the cover and pressing the magnet in all of the way, it started working perfectly.

As for the rest of the build, it was very similar to other Prusa printers. Follow the instructions, take your time, eat your gummy bears, and all will be well.

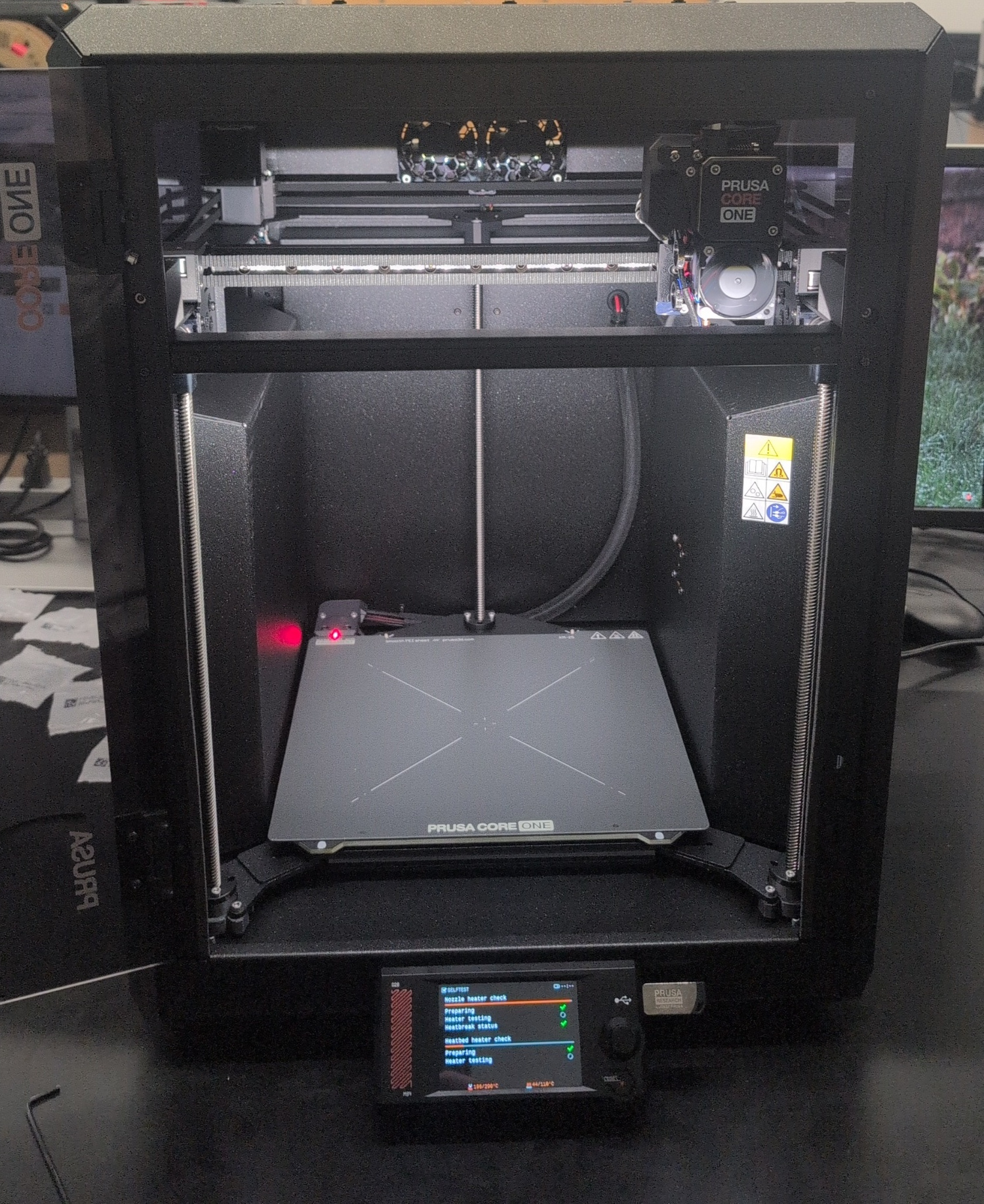

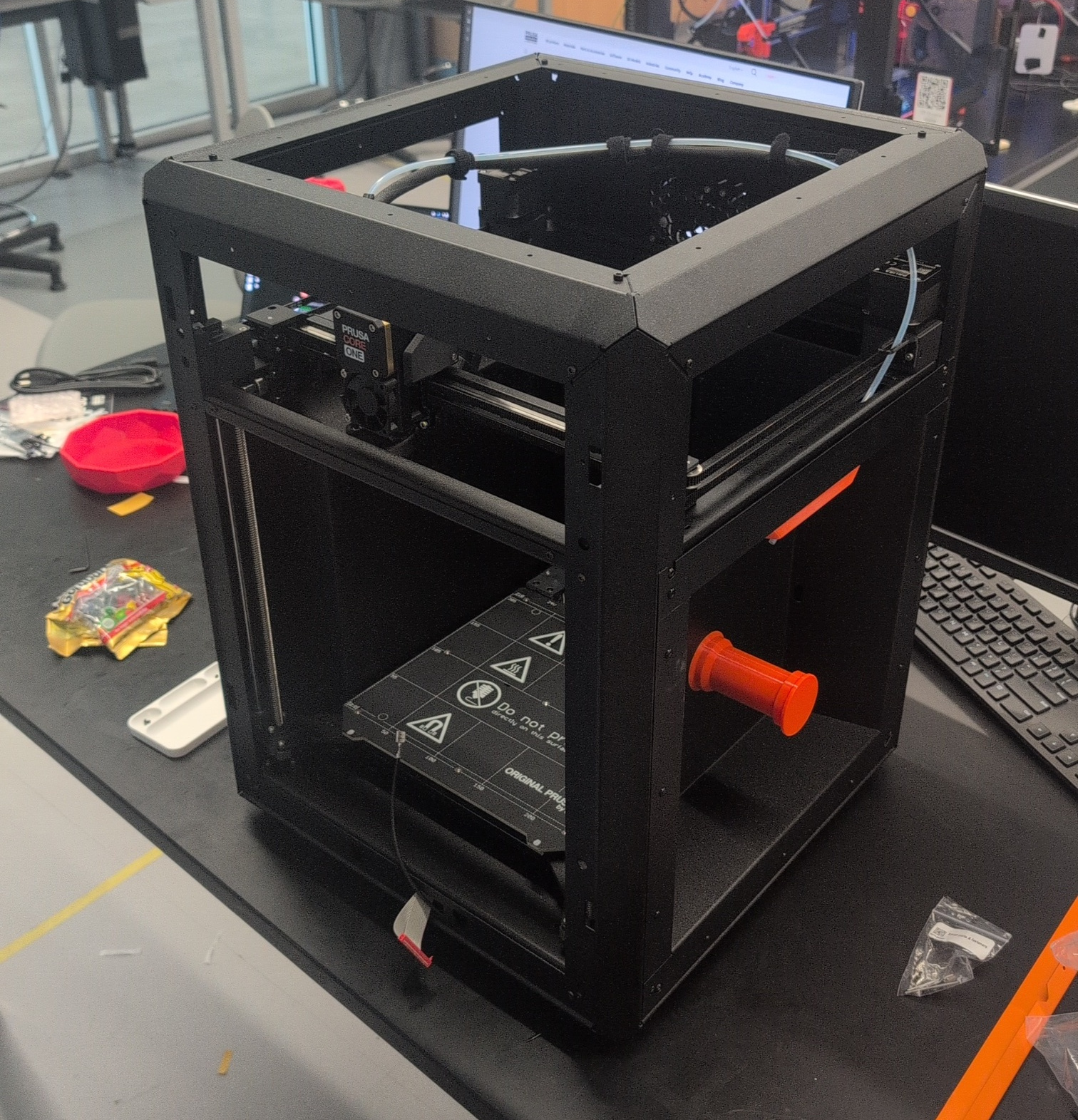

Man this Printer is Gorgeous

Once I completed the build, the first thing I thought was: “Wow, this is the best looking printer I have seen to date.” Grated, I am a little biased with Prusa’s color scheme being one of my favorites, but the sleek black and orange printed parts really puts this thing together. Prusa also did a great job in including some illumination and status lights on this printer.

First Print

Setting up the printer was a breeze. Only issue I had was getting the CoreXY system tensioned properly, but after a couple tries, the printer passed all of its self-tests and was ready to print.

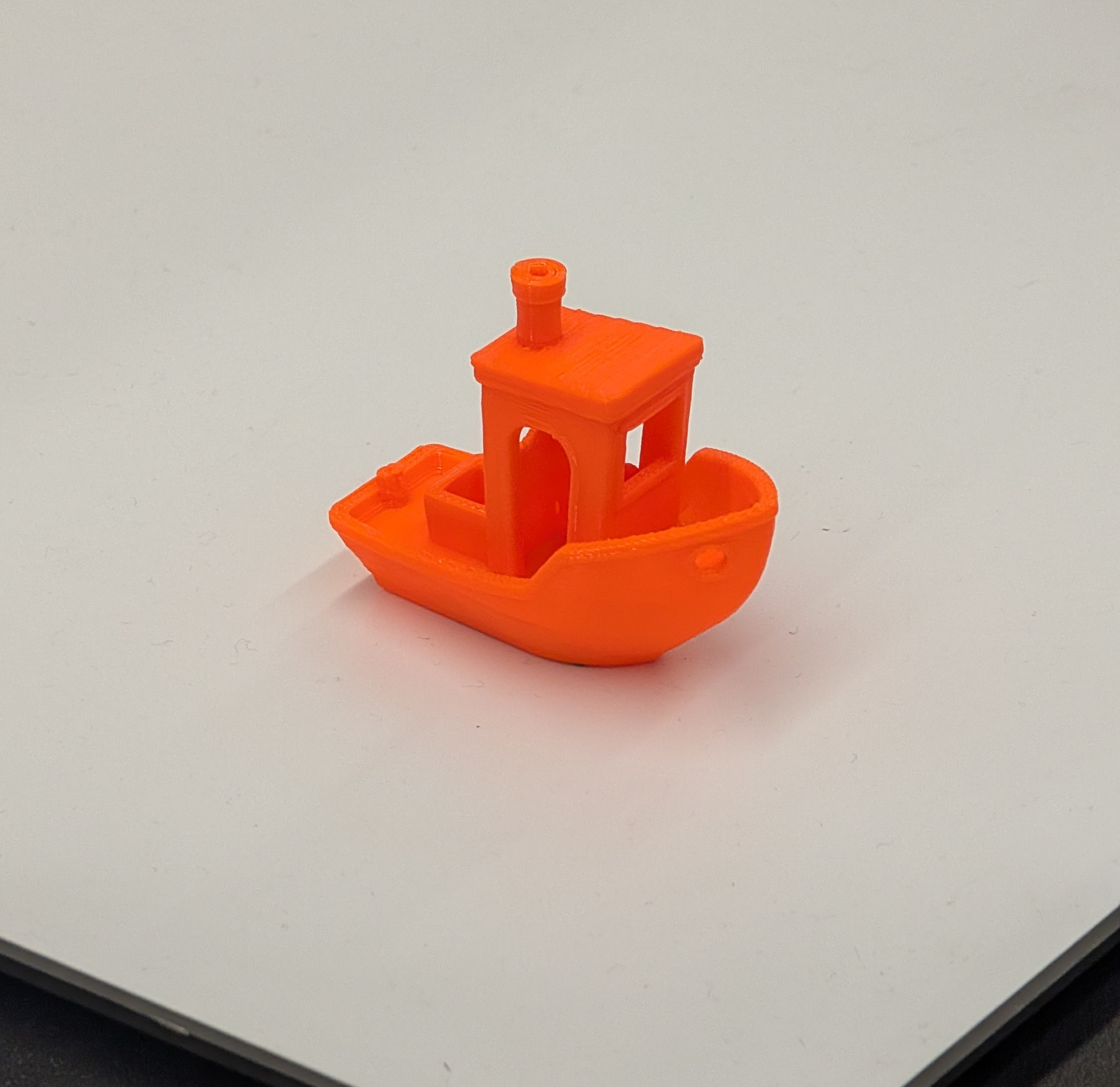

Benchy

This printer can do Benchy in 8 glorious minutes. There is a noticeable speed improvement between this printer and the Mk4s, especially after printing with the Core One for a few weeks now.

Heat Absorbing

One new part of the Core One is the actively controlled temperature enclosure. The printer is able to self-regulate its internal temperature by turning a set of fans on and off.

Something new I didn’t expect until the first print was that the printer starts off every print by getting the bed up to temperature, and then using that heat to warm up the enclosure. This was a really nice touch that helps with print reliability and quality.

One feature I hope to see in the future is an option in the slicer to skip this step. From cold, heat absorbing can take around 5-10 minutes for PETG, which has been longer than some of the prints I do. For now, you can manually skip this stage on the printer itself, or delete the gcode line associated with this.

The GCode that controls the heat-absorbing step is: G29 G ; absorb heat. You can delete

this in the “Start G-code” entry of Prusa slicer settings, under “Printers”.

Nozzle Auto Retraction

When loading/unloading filament into a Mk4s, the user has to wait for the nozzle temperature to heat up before inserting. The Core One changed this to load/unload without having to wait for the nozzle to heat up. I really appreciate this attention to detail from the engineers at Prusa.

Pros

Prusa claims all sorts of improvements with this printer, but I have a few notable favorites that I have seen so far. The Core One comes packed full of the latest and greatest from Prusa, from speed to temperature control, to new quality of life features.

You can see the rest of the specs on Prusa’s website.

Print Speed

I have not run any definite benchmarks, but I can say that this printer is noticeably faster. Naturally, this makes sense given the transition to the CoreXY extruder design cutting down on the weight carried by the two extruder motors.

Looks Great

I have already raged about this a few times now, but Prusa levelled up their ascetics for this printer. Everything is packaged in the sleek rectangular form factor without motors, power supplies, and control boards sticking out of all sides.

It’s clear the new enclosure gave the Prusa engineers lots of options to tuck away all of the printers guts, and they did a great job doing so while still allowing it to be serviceable.

A couple of my favorite touches are the orange handles and spool holder located on the side of the printer, and the custom polycarb door decals.

Print Reliability

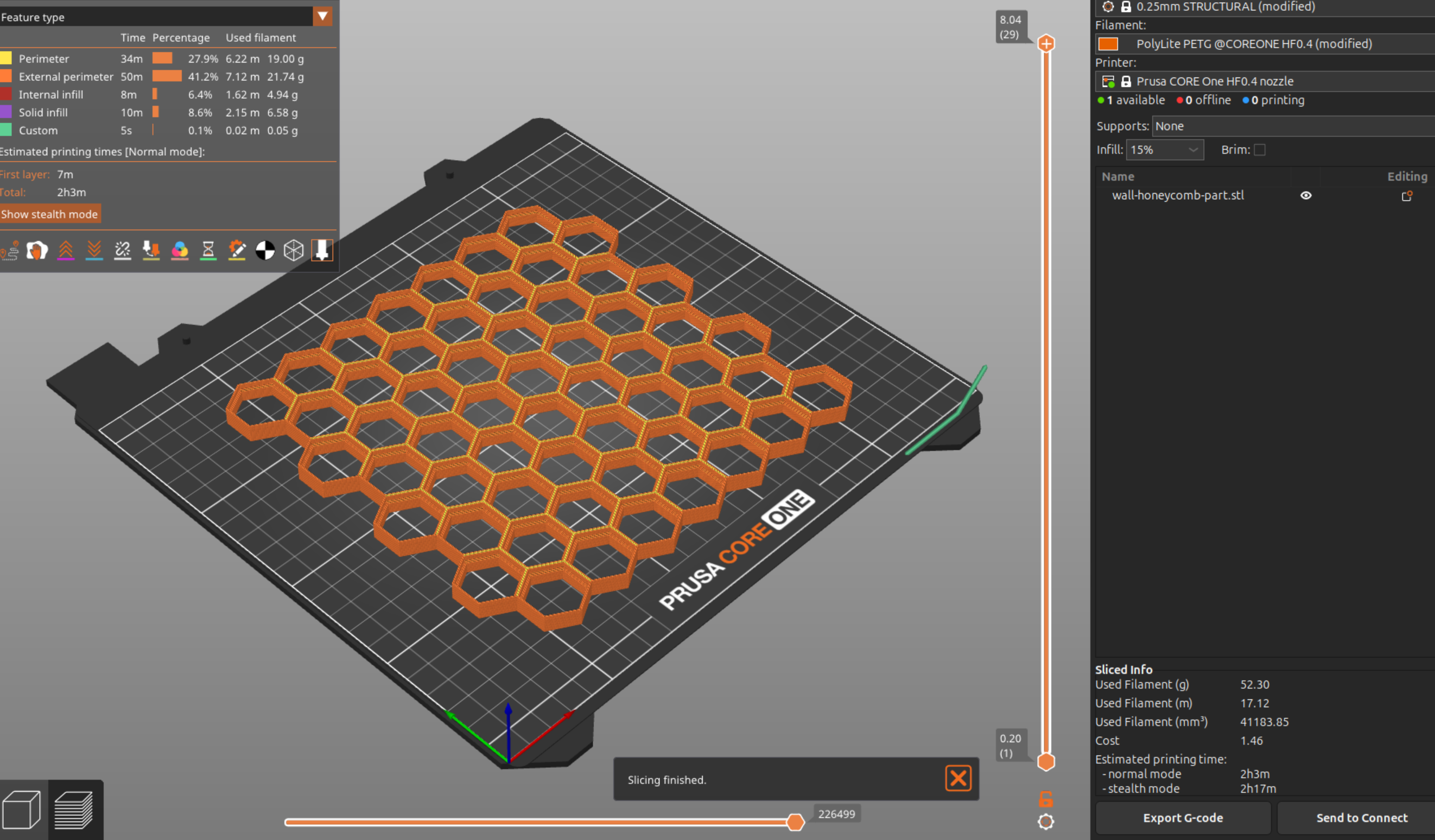

I have been printing with PETG so far almost exclusively with this printer. I have noticed that prints that cover a large bed area are more reliably sticking to the bed without the need of excessive brims. More so than the Mk4s, and certainly more than the Mk3.

This has been most apparent in some honeycomb grids that I have been printing for my wall to hang spools and cables:

Not a single one of the ~10 prints have warped at all.

Quality of life

With the release of the Core One, Prusa added a few quality of life features that I am enjoying so far.

As I mentioned earlier, the nozzle auto retraction when loading/unloading filament is a huge time saver.

Another thing that is very useful for the way I use printers, but maybe not for others is the carry handles and form factor. This printer is very easy to move, and has no protruding parts that can get caught or break off. The recesses for spools and electronics keep it from being awkward while transporting it.

I alluded to the ambient lighting earlier, but I really think it brings the whole printer together. The Core One has two light strips: the white LEDs pointing downward onto the print bed, and the RGB LEDs mounted on the print bed. The white LED lighting is absolutely necessary with the smoked out side windows, and I can always see my print perfectly. The RGB LEDs show status through color changes immediately telling the user what state the printer is in.

Cons

Price

Ok, so the elephant in the room: Price. This is not a cheap printer. In fact, it is the most expensive main-line FDM printer that Prusa has released to date.

Personally, I purchased the kit at $1,079 USD shipping included. I did pay for a little bit faster shipping, but even with that: it’s a big price tag.

If you already have a Mk4s, you can purchase an upgrade kit for $529 USD, which is a little more palatable.

If this is your first time looking at a Prusa printer, this is daunting, and I’m not denying that, so what is unique to justify this price?

- Open - The majority of Prusa’s designs are open and hackable. If you want to change something? You can

- Repairable - Prusa has a large number of printed parts in their design, as well as standard hardware. Their printers are easily repairable.

- Sustainable - Usually, you can upgrade your printer to the newest version without having to buy a whole new printer. Prusa is great at re-using parts.

Active Heating

The Prusa Core One has an actively cooled enclosure, which is an important distinction to make. The printer does use the bed to heat the enclosure up to start, as previously mentioned but does not have any heating elements to keep the enclosure warm outside of the print bed. I’m not sure how much that matters for higher-temperature prints, but an important note.

Benefits over Mk4s

So with all of this being said, why did I, and why should you buy this printer over a Mk4s? I’ll be honest, I cannot come up with a super clear-cut answer: it entirely depends on how you want to use your printer.

The reason I chose a Core One was pretty much the sunk cost fallacy. If I was going to purchase a new printer, what was a couple hundred dollars more for the latest and greatest from Prusa? I probably could have sufficed with a Mk4s, considering I typically am only printing with PLA and PETG, but since I spent the money, I want to try some more exotic materials.

Is it faster? yea, prettier? absolutely. Does the enclosure and active heating/cooling make prints more reliable? sure. But is all that worth the extra $200? I think so, yeah if you are like me and wanted a printer that just works.

Now I will say this, pricing out a Mk4s + enclosure is more expensive than the Core One, so if you care about an enclosure, just get the Core One.

There is another side to this argument too though: even if you can get by with the Mk4s, all of the new features and development is being done on the Core One. I’m sure we will see some very cool feature and accessories being offered by both Prusa and the community for the Core one that may not be back-ported to the Mk4s.

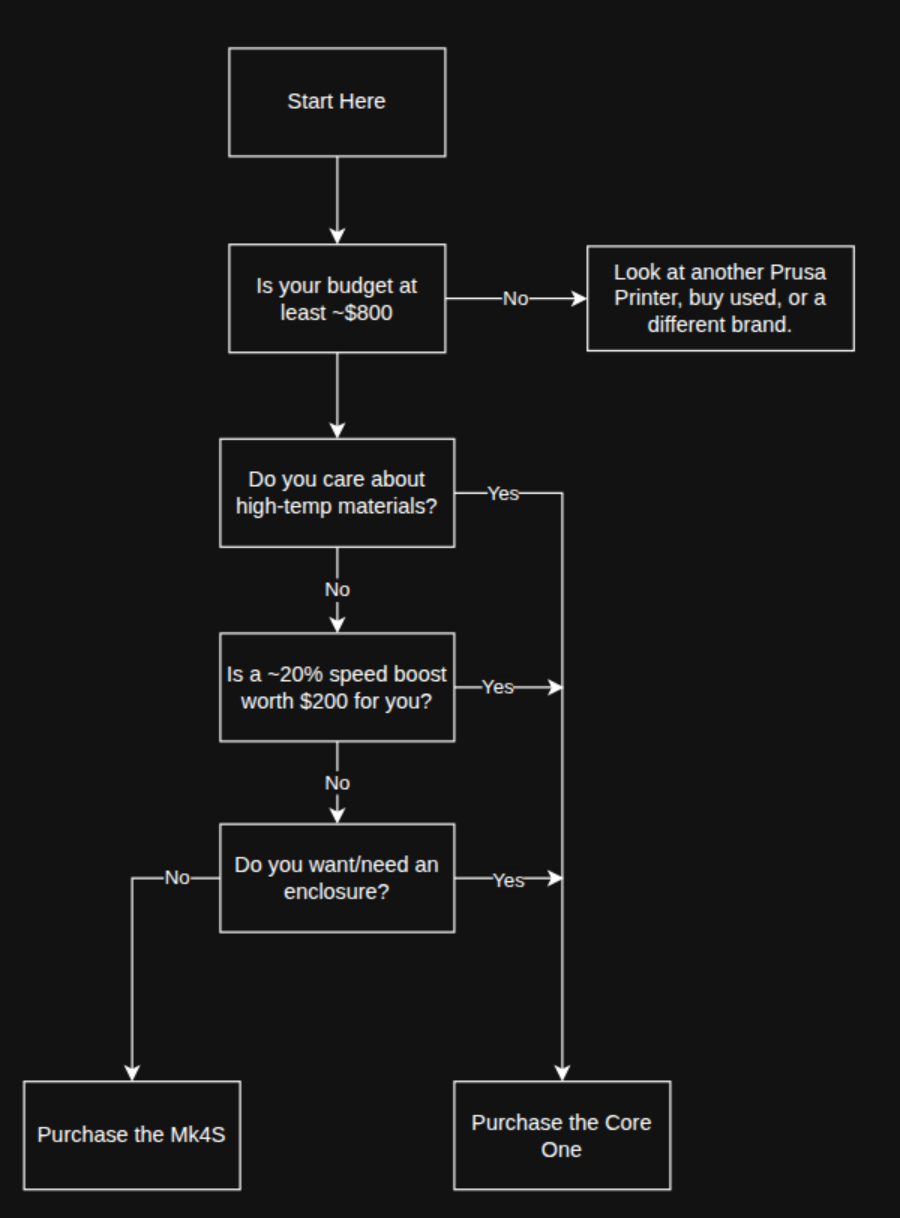

Should You Buy It?

So with all of that being said, is it worth it for you? I made a pretty simple flowchart to help you decide. Note this isn’t all-encompassing, and it’s a good idea to do your own research as well.

Wrapping Up

The Prusa Core One is a fantastic printer, packed full of new features from Prusa. I think this form-factor is the future of Prusa’s lineup of printers, and I’m excited to see what comes in the near future in terms of add-ons. It’s a solid purchase for those that want a printer they don’t have to tinker with for good quality. For those that want to tinker, most of the design is open and hackable. In the month or so I have been using it, I have been blown away by how far we have come in consumer 3D printing technology.

Last Updated: 2025-09-12